MaoWei Machine

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

Product series

- Carton box printing machine

- Box gluing machine

- Box stitching machine

- Die cutting machine

- Corrugated plant

Hot selling product

Including Flexo printing Machine and Digital Printing Machine.

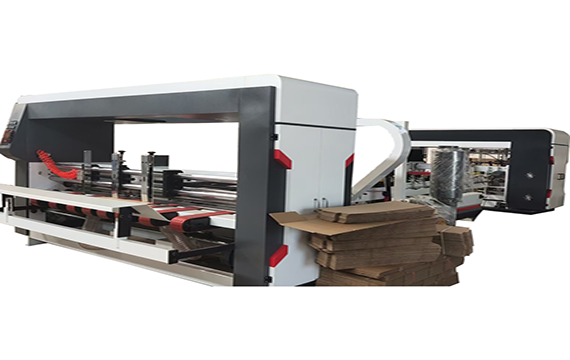

We have Automatic Folder Gluer Machine and Semi automatic folder gluer machine.

Automatic corrugated box stitching machine and Manual carton box stitching machine.

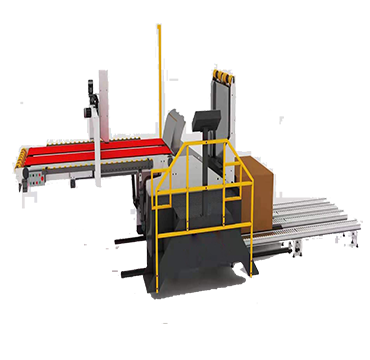

Inline Flexo Printing Machine and Automatic Folder Gluer Stitcher.

Flute Laminating Machine and Thermal film laminating machine .

Company competitive advantag

- Product quality CE certification, customers enjoy a 12-month warranty.

- Professional foreign trade team from negotiations to after-sales, so that customers worry.

- Strict quality control before sale, 24 hours after sale online to solve any problem for customers.

How to work

- Brief introduction, confirm the type of carton packaging machinery suitable for customers.

- Make drawings.

- Prepare each component.

- Assemble.

- After the machine is finished, the test run begins.

- Send video inspection to customers or come to the factory for inspection.

- After confirming that there is no problem, package and ship

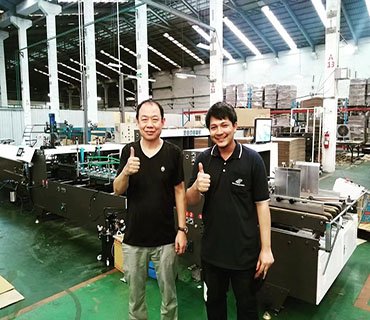

Case studiesOur packaging machinery and equipment are sold all over the world and are recognized by customers.

Our packaging machinery and equipment are sold all over the world and are recognized by customers.

Customers from Ethiopia purchase a complete set of carton box making machine in our company.

Customer from Saudi Arabia, purchase of Corrugated board production line and complete carton box making machine equipment.

Customers from Thailand purchase Automatic Folder Gluer Stitcher and Inline flexo printing machine in our company.

Customers from South Korea purchase Digital corrugated printer machine and Carton box making machine in our company.

Customers from Iraq purchase Carton box printing machine and Automatic folder gluer machine from our company.

Customers from South Korea purchase fully Flexo corrugated box printing machine and Automatic Folder Gluer Stitcher from our company.

Automatic Folder Gluer Stitcher machine with secondary correction function, eliminate the size of the mouth, reduce the scrap rate. With differential correction adjustment function, completely eliminate scissors and forks, folding more accurate.

Carton box printing machine the whole process of adsorption bellows with paper press wheel transmission, printing and overprinting accuracy is higher. Full computer to measure the thickness of cardboard, pressure one key automatic adjustment system, automatic correction, to the plate system.

Support custom carton machine

In order to meet the needs of different customers, we will provide customers with the most suitable solutions in the aspects of machine shell modeling, machine performance, brand OEM, etc. Highlight the uniqueness of customization.

Why choose us

- In the carton packaging industry quality and affordable price are what we are here to do for our clients.

- Delivery on time is our NO.1 topmost priority.

- 24 hours online after-sales service, do not delay customer production.

- Have foreign installation and commissioning engineers.

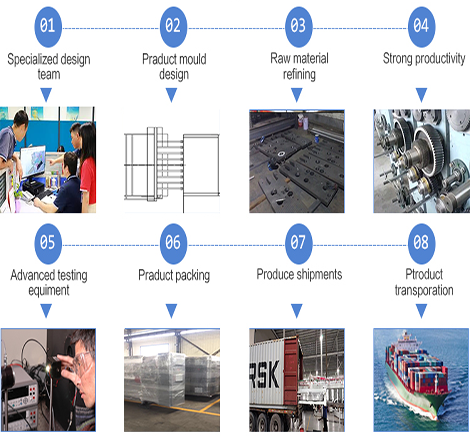

Quality controlOur company guarantees the quality of every packaging machine.

Our company guarantees the quality of every packaging machine.

We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machine.

We customize the plan according to the customer’s needs, design complete drawings and correct data.

After the completion of the machine, the quality supervision department will test the performance of the machine.