Skip to contentNail box process common quality problems and treatment methods Episode

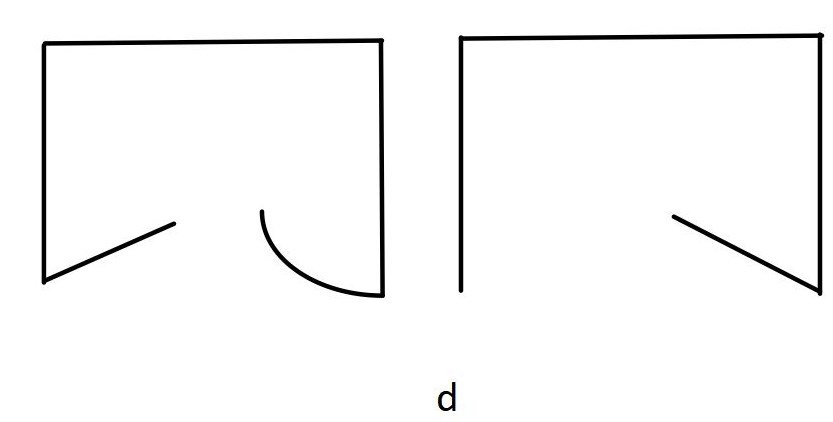

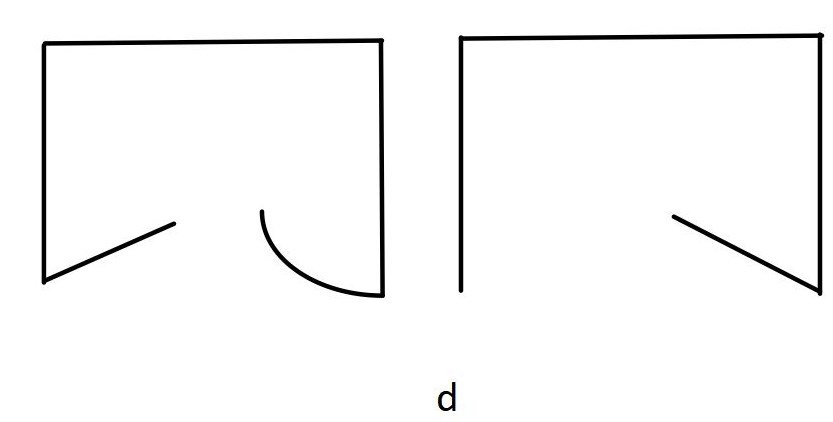

- The stitching is not equal in length. (Figure d)

Cause: The wire feed is delayed or blocked, and the width and thickness of the flat wire are uneven or damaged.

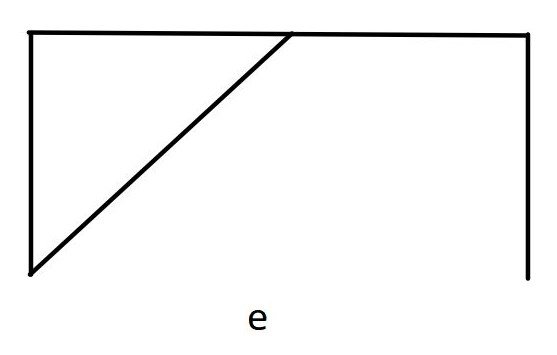

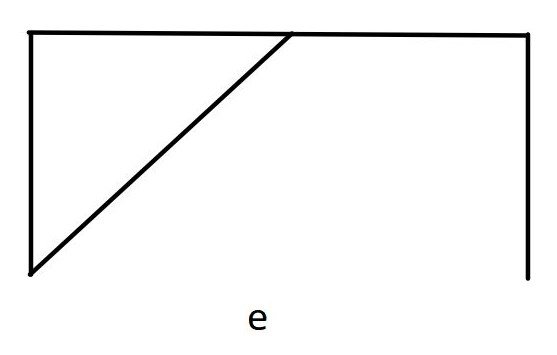

Solution: Adjust the pressure of the wire feed wheel to replace the flat wire that does not meet the requirements. - The stitch is crooked.(Figure e)

Cause: The Angle of the foot groove of the bottom die is wrong, or the bottom die is seriously worn.

Solution: Adjust the groove of the return foot to align the two tips of the top knife or replace the bottom die. - Nail 5 layers of box face is broken.

Cause: The box pieces are not placed flat, the two sides of the bottom die are high and low, and the distance between the hammer head and the bottom die on the bracket arm of the nailing machine is too large.

Solution: When nailing the box, put the box piece flat, the high face does not break the height of the bottom die on this side, and adjust the distance between the small hammer head and the bottom die of the bracket arm of the nailing machine. - Overlap nail、less nail

Cause: Repeated nails or flat wires appear broken.

Solution: Repair nail box machine, nail box strictly according to technical quality requirements.

Scroll to Top