Feeding unit

- The pneumatic side-capture device (operating side) allows you to set the frequency of paper capture on the screen.

- The transmission shaft is equipped with a friction clutch to prevent accidental operation and damage to the machine.

- Active motor startup automatic protection device.

- The machine table is made of all-steel material, which is more stable. The smooth side has U-shaped grooves without sharp edges, preventing any harm to personnel.

- The system is controlled by 8 full-adhesion belts, ensuring more precise, smoother and more durable paper feeding, thereby maximizing the long-term normal operation of the machine.

- Manually adjust the air door to control the vacuum flow and pressure, in order to match the size of the cardboard.

- The air volume can be adjusted to control the vacuum flow and pressure, in order to match the size of the paperboard.

- By the previous positioning, the paper feeding error is reduced and the paper feeding accuracy is improved.

- The positions of the left and right baffles are controlled electrically. Parameters can be directly input on the screen to complete the positioning.

- The rear paper holder is electrically controlled to move forward and backward, and the setting speed is accelerated.

- The gap of the front panel can be adjusted manually, which is convenient and fast.

- Continuous or intermittent paper feeding is available.

Folding unit

- This section is composed of a 70mm bottom synchronous belt and a 60mm wide guide belt.

- The second and fourth folding lines on both sides are completely adhered together at a 180-degree angle.

- The left and right drive wheels are adjusted according to different positions to ensure smoother operation of the folding box. The lower bearings support and guide the belt to operate correctly.

Stitching unit

- The corrected cartons are conveyed into the box-folding section by four flat wheels. These 8 rubber wheels can adjust themselves according to the thickness of the paperboard.

- The nail box section can apply two nails at once. The single nail head is equipped with a high-speed motor. Under the coordinated control of the servo system, the brake, and the electric eye, the nail application speed exceeds 600 nails per minute. This speed is directly related to the spacing between the nails. When the nail box is switched to the blanking mode, the nail head will automatically rise. The speed of the nail box section is coordinated with the main machine, and the entire machine can also move horizontally left and right.

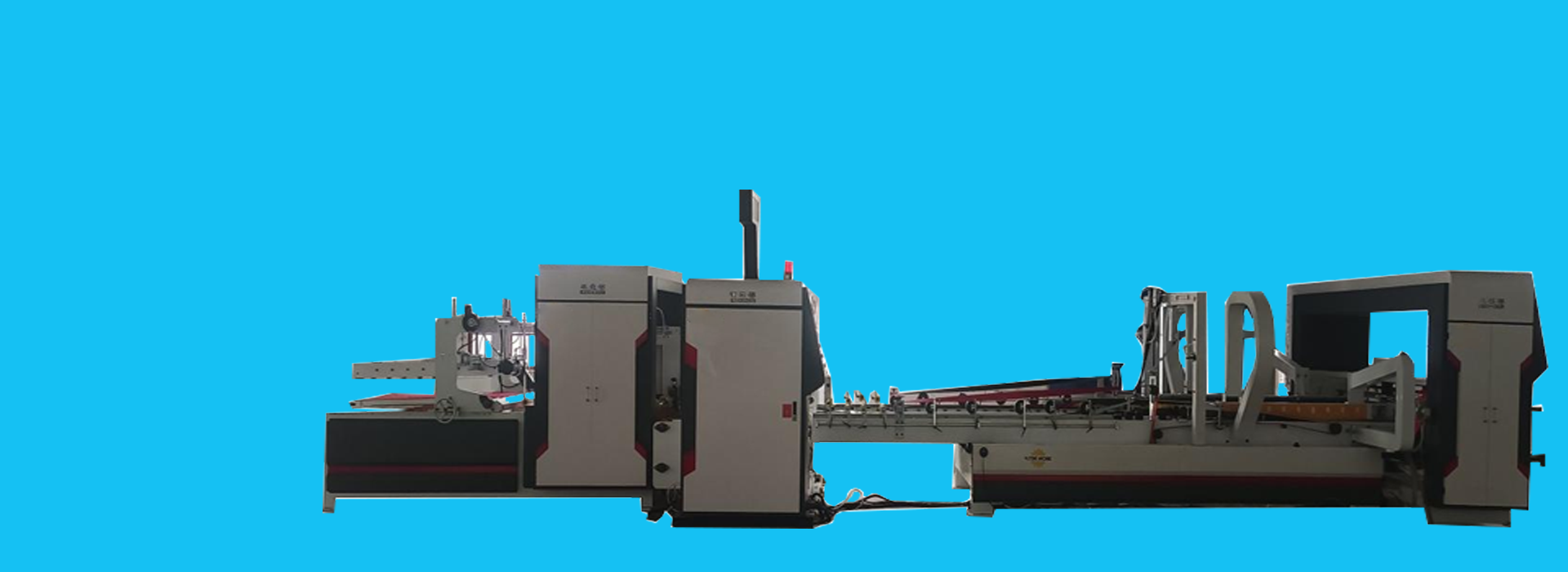

Overall performance features of the machine

- The fastest box-nailing speed is 700 nails per minute, and the box-filling speed is 120 meters per minute. The speed is very fast, significantly improving production efficiency.

- The entire machine is controlled by PLC and touch screen, and can also be operated through buttons.

- Automatic paper feeding, automatic box gluing/boxing, automatic folding, automatic correction, automatic counting, automatic stacking.

- The main drive is of synchronous belt wheel type, ensuring smooth operation and precise transmission.

- The main motor adopts dual-frequency control, ensuring stability and saving power.

- The guide plates of each part are adjusted by a tooth rod motor, ensuring precise positioning and being simple and convenient to operate.

- Using the suction belt for paper feeding, the structure is simple, the speed is fast, and the paper feeding is accurate.

- The glue application roller can be adjusted at will, enabling the completion of various requirements for paper box gluing.

- It has a secondary correction function, eliminating large and small openings and reducing the waste rate.

- It has a differential correction adjustment function, completely eliminating the scissors fork design and enabling more precise folding.

- The paper collection and shaping department automatically counts, shapes, stacks into packages, and outputs in complete packages. It is fast and highly accurate.

- The pressure of the counting section is adjusted according to the sample box. A photoelectric counter is used for accurate counting.

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

Technical Specifications

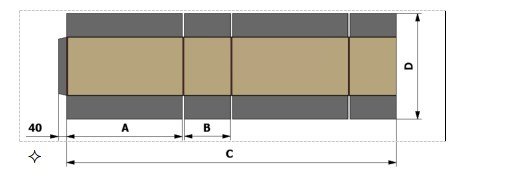

1)Stitching size

| Maximum C size | 2400mm |

| Minimum A size | 200 mm |

| Maximum A size | 800mm |

| Minimum B size | 150mm |

| Maximum B size | 750mm |

| Minimum cardboard size (DxC) | 320x650mm |

| Maximum cardboard size (DxC) | 1200x2400mm |

2) Gluing size

| A | Min.130- max. 800 |

| B | Min.80 – max. 800 |

| C | Min420 – max.2400 |

| D | Min.170 – max. 1200 |

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.