Feida paper delivery part

- European technology manufacturing precision feida head card, corrugated and gray board multi-purpose.

- Four suction four send, (more than 1300 four suction five send) can be adjusted according to the paper deformation suction Angle and height.

- Unique paper receiving mechanism, suitable for different paper deformation.

- High-speed feida head is made of special aluminum alloy, all parts are imported.

- Paper feeding switch prevents false following of paper.

- Double flying-head collision detection device.

- Main and secondary feeding paper non-stop switching.

- A set of pre-coding paper mechanism is optional.

- Fish-scale paper feeding, smooth and accurate.

- Paper table fine-tuning mechanism, non-stop adjustment.

Paper feed stand

- The advanced control system is used to control the speed device of paper feeding to make the paper delivery stale and reduce collision.

- Photoelectric double detector.

- Import paper conveyor belt.

- Ultra-Wear Resistant polyurethane paper transport wheel.

- Adjustable rubber wheels and brush wheels ensure precise positioning of arrival front and side return.

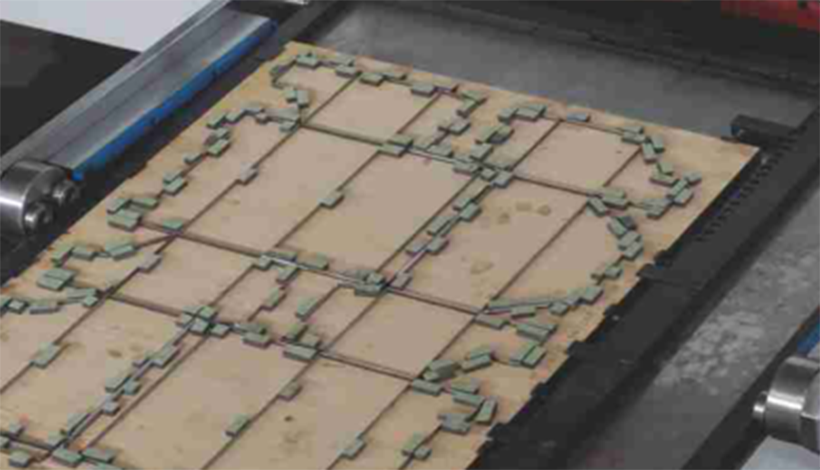

Die cutting part

- The pressure bearing parts are high strength ductile iron-QT600-3,cast by special technology,with high strength and permanent deformation.

- Nickel-chromium-molybdenum-gold steel crankshaft with special process for imported steel from Germany.

- Taiwan imported ultra-wear-resistant worm gear and worm.

- Convenient and fast tool template turning device.

- Strong oil supply lubrication system.

- High precision 240 degree intermittent mechanism.

- Pneumatic locking device is safe and fast.

- High speed rotary joint.

- Maximum pressure is 300 tons (maximum pressure of press type is 600 tons)

- Using advanced honeywell main motor (optional configuration),the die cutting speed can reach 7500 sheets per hour.

- Die-cutting plate frame adopts intermediate positioning system with fine-tuning device.

Receiving department

- Automatic paper leveling device,paper receiving two-way blowing device to ensure.

- Thick and thin paper can collect paper neatly.

- Paper collecting department is equipped with control to realize more humane operation.

- Photoelectric paper receiving to ensure paper receiving regularly

- Automatic lifting control system of paper receiving table.

- Manual paper collection.

- Main chain protective device.

Machine characteristics

This machine has achieved automation throughout the process from paper feeding, die-cutting, waste removal to paper collection. The human-machine interface is used to display the working speed of the machine, the number of processed pieces, the running time of the machine and the working status. Realize dynamic monitoring of the input and output points as well as various faults of the programmable controller, making fault elimination and operation more convenient.

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

- Technical Specifications

- Main parts and original

| 1.Die cutting | flat |

| 2.Max.paper size | 1060*760mm |

| 3.Min.paper size | 450*360mm |

| 4.Max.die-cutting size | 1050*750mm |

| 5.Min.mouth size | 8mm |

| 6.Max.working pressure | 300t |

| 7.Scope of application | White board ≥100g corrugated paper thickness≤9mm |

| 8.Die cutting precision | ± 0.1mm |

| 9.Max.working speed | 7000 Second/T |

| 10.Max.discarding Speed | 6500 Second/T |

| 11.Max.heap height | 1600mm |

| 12.Max.paper collecting height | 1500mm |

| 13.Main motor power | 11kw |

| 14.Rated power | 23kw |

| 15.Machine weight | 16t |

| 16.Overall dimension | 7849*4147*2182mm |

| No. | Name | Brand | Original |

| 1 | Photoelectric switch | MEIJIDENKI | USA |

| 2 | Human Machine Interface | Delta | Taiwan |

| 3 | Button | Schneider | France |

| 4 | AC relay | Schneider | France |

| 5 | Solid state relay | FOTEK | Taiwan |

| 6 | PLC | Delta | Taiwan |

| 7 | Klaxon | QLIGHT | South Korea |

| 8 | Electromagnetic valve | SMC AirTAC | Taiwan |

| 9 | Decantor | AirTAC | Taiwan |

| 10 | Motor circuit breaker | Schneider | France |

| 11 | Servo motor | Delta | Taiwan |

| 12 | Main motor | yao’jiang | shang’hai |

| 13 | Gear motor | ZD | Taiwan |

| 14 | Oil pressure shut-off switch | ARK | South Korea |

| 15 | Pneumatic clutch | OM | Italy |

| 16 | Feeding paper clutch | SUNWOOD/OGURA | Japan |

| 17 | The torque limiter | JASU | Taiwan |

| 18 | Intermittent divider | Hunter | Taiwan |

| 19 | Vacuum pump | heng’dong | jiang’su |

| 20 | Feeder head | EAP | Taiwan |

| 21 | Feeder suction mouth | SILENT | Sweden |

| 22 | Dental row transmission chain | IWIS | Germany |

| 23 | Other transmission chain | TYC | Taiwan |

| 24 | Dental row | JASU | Taiwan |

| 25 | Bearing | NSK | Japan |

| 26 | Rotary joint | SMC | Japan |

| 27 | Timing belt | CONS | Taiwan |

| 28 | Delivery belt | CONS | Taiwan |

| 29 | Die spring | Japan | |

| 30 | Worm and worm gear | Lifa | Taiwan |

| 31 | Circulating oil cooling system | Weiliang | Taiwan |

| 32 | Cooling fan | Jianzhun | Taiwan |

| 33 | Heat exchanger | Ray ban | USA |

| 34 | Microcomputer Electric Lubrication Pump | Yongsheng | Taiwan |

| 35 | Encode | Omran | Japan |

| 36 | Seal ring | Escort Seal | Taiwan |

| 37 | Inverter | Danfoss, Halip. | Denmark |

| 38 | Machine body | Nodular cast ironQT600-3 | China |

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.