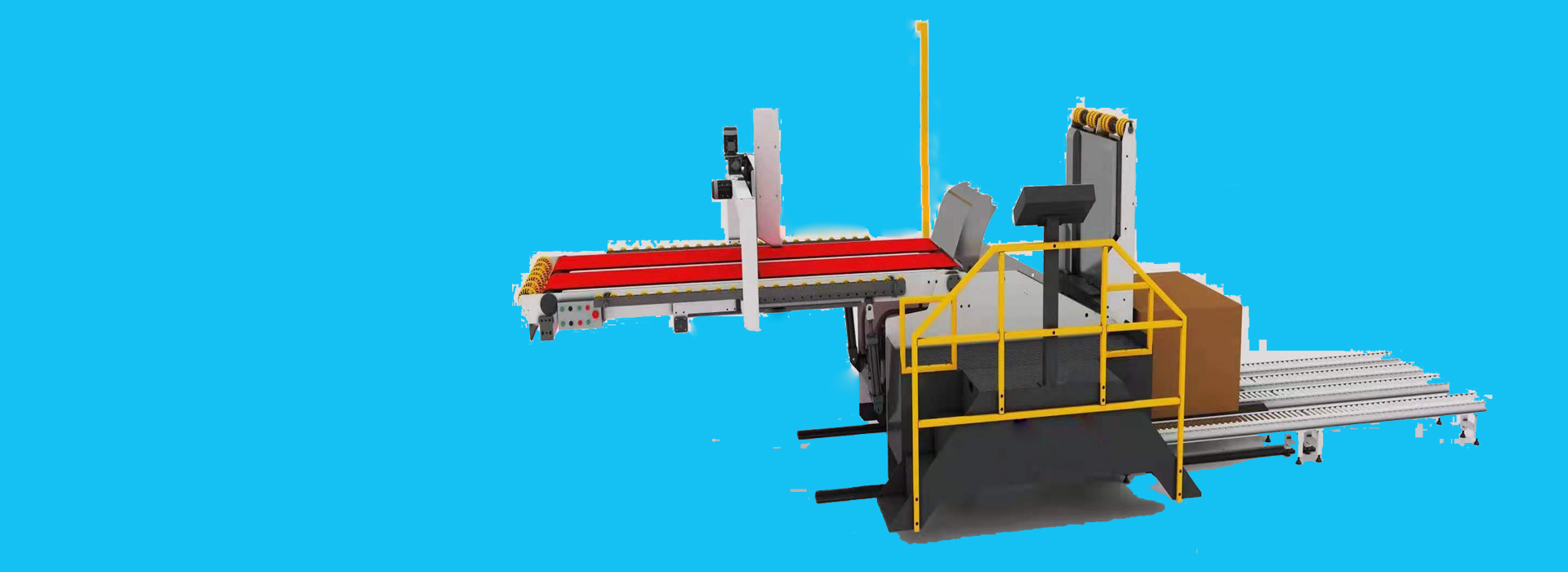

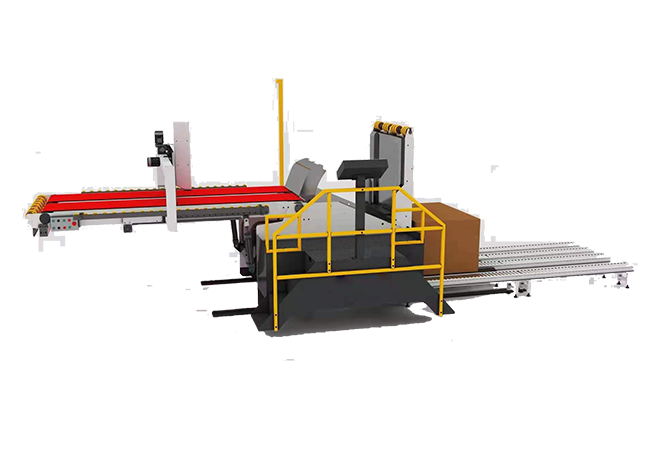

- The conveyor belt delivers the dumped cardboard to the stacker paper feeding section. After passing through the stacker paper feeding section, the cardboard automatically arranges in a fish-scale pattern and is then conveyed by the belt of the horizontal conveying section to the paper feeding section of the glue and staple integrated machine.

- The two sides of the cascading conveying section are equipped with automatic alignment devices. The alignment devices can be electrically adjusted in position (alignment stroke: 100mm).

- At the front end of the horizontal conveyor belt, there is an automatic longitudinal paper pressing device. The conveying speed is adjusted according to the vehicle speed by frequency variation.

- The entire machine can be moved vertically.

- The horizontal conveyor belt is automatically controlled by photoelectricity.

- The complete machine’s power-actuated crawler logistics system is provided for delivery by the equipment factory.

- Touchscreen computer control.

Mechanical Specifications

- Maximum paper feeding size: 1200 × 2800 mm

- Minimum paper feeding size: 260 × 755 mm

- Maximum paper loading height: 2000mm

- Maximum paper loading weight: 1200kg

- Maximum paper feeding speed: (For paper thickness less than 4mm, ≥ 400 sheets per minute);Cardboard thickness less than 8mm: ≥ 280 sheets per minute

Technical points

- Control and Intelligent Interface.

- Equipped with a horizontal conveying section.

- Equipped with a platform lifting mechanism.

- The splines are of the tooth fork type.

- Integrated Mobile Alignment Device for the Longmen Machine.

- Shaft lift/drop

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

- Component brand

| Tank manufacturer brand | FQS |

| Hydraulic unit power | 11HP |

| Hydraulic cooling method | Air-cooled |

| Oil pressure solenoid valve | YUKEN (Japan) |

| Cylinder | FQS |

| Fuel tank capacity | 200L |

| PLC | Panasonic |

| Operation interface | Touch screen |

| Control element | Schneider |

| Linear guide rail | Shangyin |

| Motor reducer motor | Shengbang |

| Frequency converter | Delta |

| Pneumatic components | Yadeke |

| Proximity switch, photoelectric switch | Omron / Otonix |

| Servo motor | Yaskawa |

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.