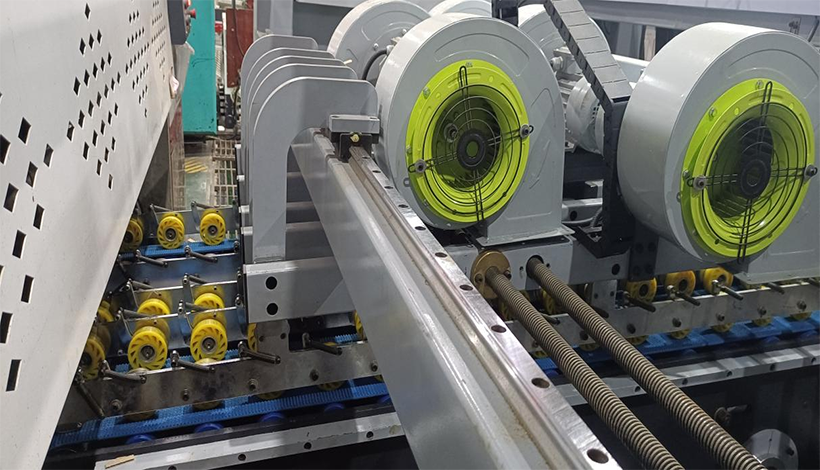

- The latest industrial design, all the gear covers adopt high quality stainless steel, beautiful and durable.

- Uniformly driving, pneumatic interlocking, each single unit OPEN/CLOSE with alarm and safety protection device.

- Each unit is equipped with an emergency stop switch, which can stop the movement of each unit internally to ensure the safety of the internal operators.

- Maximum speed: 260pcs/min. This effectively enhances production efficiency.

- All the main drive gears are made of special imported material (20CrMnTi), undergo carburizing and quenching, and are precisely ground. They are durable and long-lasting. The gear lubrication is provided by an oil pump spray system.

- All the control electrical appliances are of international top brands, which are stable and durable. The main control electrical box is equipped with an industrial constant-temperature air conditioner. Each branch electrical appliance is also equipped with dust-proof and heat-dissipating devices to ensure stable and reliable operation performance.

- The entire machine is equipped with an automatic oil circuit balancing system and an automatic circulation lubrication system.

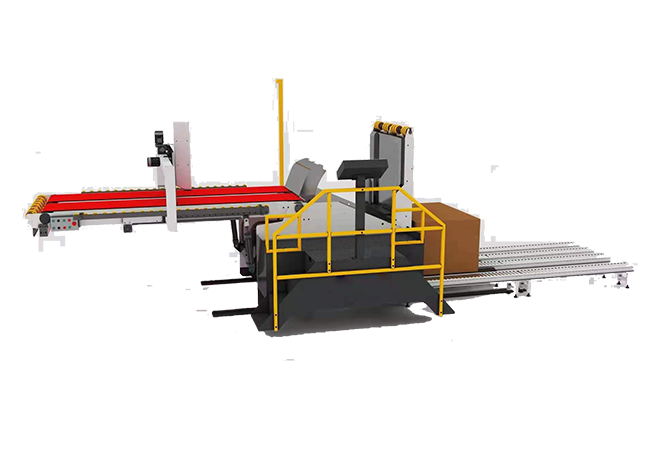

Waste removal unit

- Move the paper belt to a separate position.

- The edge of the paper conveyor belt is equipped with a paper pressing wheel, a fan and a brush, which can thoroughly clean up the waste paper and waste materials.

- Guide wheel device, upper and lower belt clamping for transmission.

- Electric left and right movement, easy adjustment of size and dimensions.

Machine Features

- The latest industrialized appearance design. All the gears on the entire machine are covered with high-quality stainless steel, which is both beautiful and durable.

- The entire machine is driven uniformly, with pneumatic interlock. Each unit can be opened or closed automatically or independently. During movement, continuous ringing alerts are provided to remind the operators and ensure their safety.

- Each unit is equipped with an emergency stop switch, which can stop the movement of each unit within the unit itself. This ensures the safety of the internal operators.

- Maximum speed: 260 sheets per minute. This effectively enhances production efficiency.

- All the main drive gears are made of special imported material (20CrMnTi), undergo carburizing and quenching, and are precisely ground. They are durable and long-lasting. The gear lubrication is provided by an oil pump spray system.

- All the control electrical appliances are of international top brands, which are stable and durable. The main control electrical box is equipped with an industrial constant-temperature air conditioner. Each branch electrical appliance is also equipped with dust-proof and heat-dissipating devices to ensure the stable and reliable performance of the operation control.

- The entire machine is equipped with an automatic oil circuit balancing system and an automatic circulation lubrication system.

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

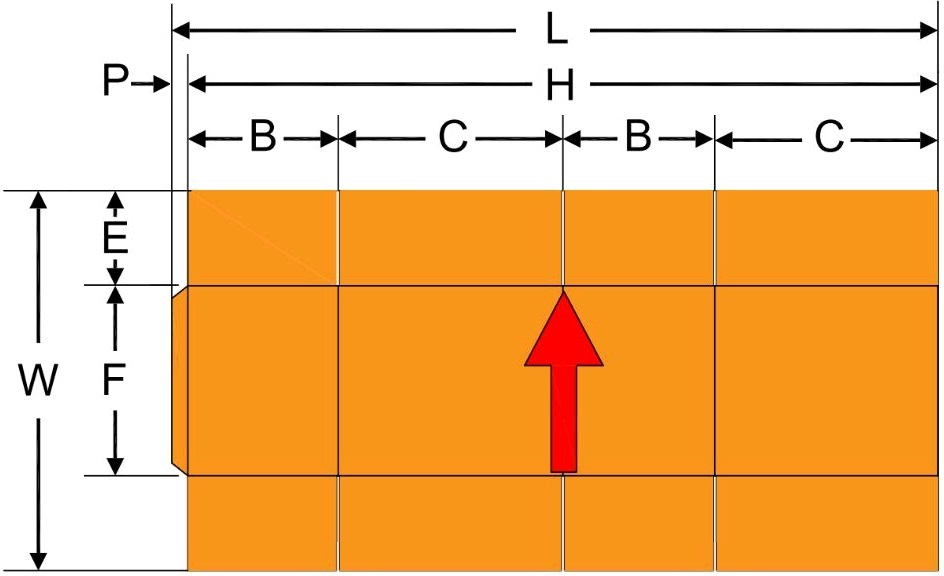

- Main Parameters

| ITEM | CONTENT | MIN. | MAX. | |

| L | Cardboard Feeding Width | 1040 | 2900 | |

| W | Cardboard Width | 350 | 1200 | |

| W | Skip Feeding | 350 | 1400 | |

| F | Box Height | 110 | 600 | |

| E | Slotting Depth | 0 | 300 | |

| P | Glue Flap | 25 | 45 | |

| WxH | Max. Printing Area | 1200x2800mm | ||

| BxCxBxC | Min. Slotting Space (Revised Knife) | 260x80x260x80mm | ||

| Printing Plate Thickness | 7.2mm | |||

| Printing Accuracy | ±0.5mm | |||

| CardboardThickness | 1.5- 11mm | |||

| Speed (sheets/min.) | Max. Speed | 260sheets/min | ||

| Economic Working Speed | 150-260sheets/min | |||

| Total Power | 178 Kw | |||

| Working Power | About 120 Kw | |||

| Frame Thickness | 60mm | |||

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.