2000mm High speed stitcher machine(Double servo)

- Single nails, double nails or reinforced nails (with double nails at both ends and single nails in the middle section) can be completed at one time, which can meet the different nail type demands of various customers.

- The size of the carton and the adjustment of the nail distance of the carton can be completed in just one minute, greatly saving time and being convenient to operate.

- There are both box lids and box without lids. (Whether to add lids or not depends on the specific requirements and should be specified when ordering the machine.)

- The front-end paper feeding section has an automatic counting function. The paper feeding platform is equipped with an optical sensor device, which automatically rises during paper feeding.

- The rear section has an automatic counting function. The finished products can be sorted and sent to the end of the conveying machinery in sets according to the preset quantity (1-99), making it convenient for packaging and tying up.

- Mechanical speed: 600 nails per minute; suitable for three-layer and five-layer (for seven-layer orders, please specify)

Product Description

- WELINK touch screen operation, parameters, nail spacing, nail quantity, nail type, rear guard plate, easy and quick adjustment. The entire control system adopts the Japanese Omron PLC control system. The rear electric guard plate is driven by a stepper motor.

- The photoelectric switch adopts the Omron brand, and the proximity switch adopts the Omron brand as well.

- Switching power supply – Schneider.

- The protectors, contactors and thermal protection devices are provided by Schneider.

- The intermediate relay is of the Schneider brand.

- Button switch: Schneider.

- The bearings used in this machine are from the original factory in Harbin. This machine is a synchronous belt drive system, with low noise and small error. The synchronous pulleys of the synchronous belt are produced in Foshan, Guangdong. The slide rails of the machine head are made of ball-milled cast iron and undergo high-frequency quenching treatment. The driving gear, driven gear, wire feeding wheel, and wire pressing wheel are made of 40R material and undergo quenching, tempering, fine grinding, and nitriding processes, resulting in high precision and low error. The punch is made of imported SKD11 material, and the nail mold is made of imported tungsten steel. The small parts of each part of the machine head are formed and ground to achieve high precision and low error. The motor is from Shanghai Oute.

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

- Electrical system

- Technical Specifications

| NO | Name | Brand |

| 1 | Servo | Ourui, China (Yaskawa or Mitsubishi can be selected according to customer requirements) |

| 2 | Reducer | Liming,Taiwan |

| 3 | PLC | Omron Japan |

| 4 | Touch screen | WEINVIEW |

| 5 | Switching power supply | Schneider |

| 6 | Protector | Schneider |

| 7 | Contactor | Schneider |

| 8 | Thermal protection | Schneider |

| 9 | Medium intermittent appliance | Schneider |

| 10 | Terminal row | Chint |

| 11 | Circuit breaker | Schneider |

| 12 | Proximity switch | Omron Japan |

| 13 | Photoelectric switch | Omron Japan |

| 14 | Push button switch | Schneider |

| The above devices are 100% genuine devices, to prevent fake and shoddy. When the purchased parts used in the machine are upgraded or updated, they will be replaced with the same brand quality no less than the existing brand, and the seller reserves the right not to give further notice. | ||

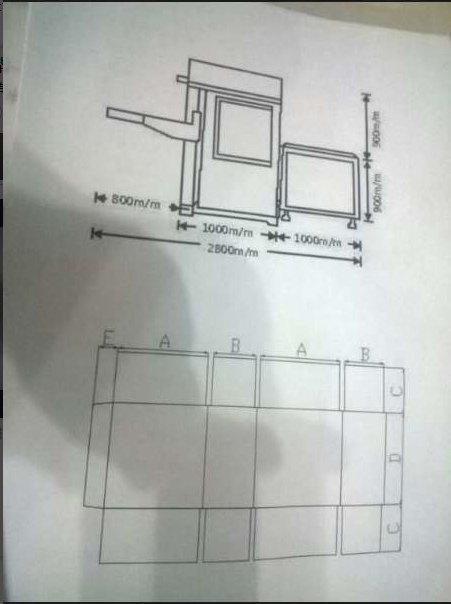

| Max.size(A+B)x2 | 3980mm | Min.length A | 250mm |

| Min.size (A+Bx2 | 740mm | Max. Length D | 2000mm |

| Max.size (C+D+C) | 3000mm | Min.length D | 150mm |

| Min.size(C+D+C) | 250mm | Max. nail tongue width E | 40mm |

| Min. shake cover C | 50mm | Max.feed paper width | 900mm |

| Max. Shake cover C | 560mm | Machine width | 2850mm |

| Max. Width B | 850mm | Machine weight(T) | 2T |

| Min. Width B | 120mm | Speed(nail/min) | 600 |

| Max. Length A | 1140mm | Nail number | 1-99 |

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.