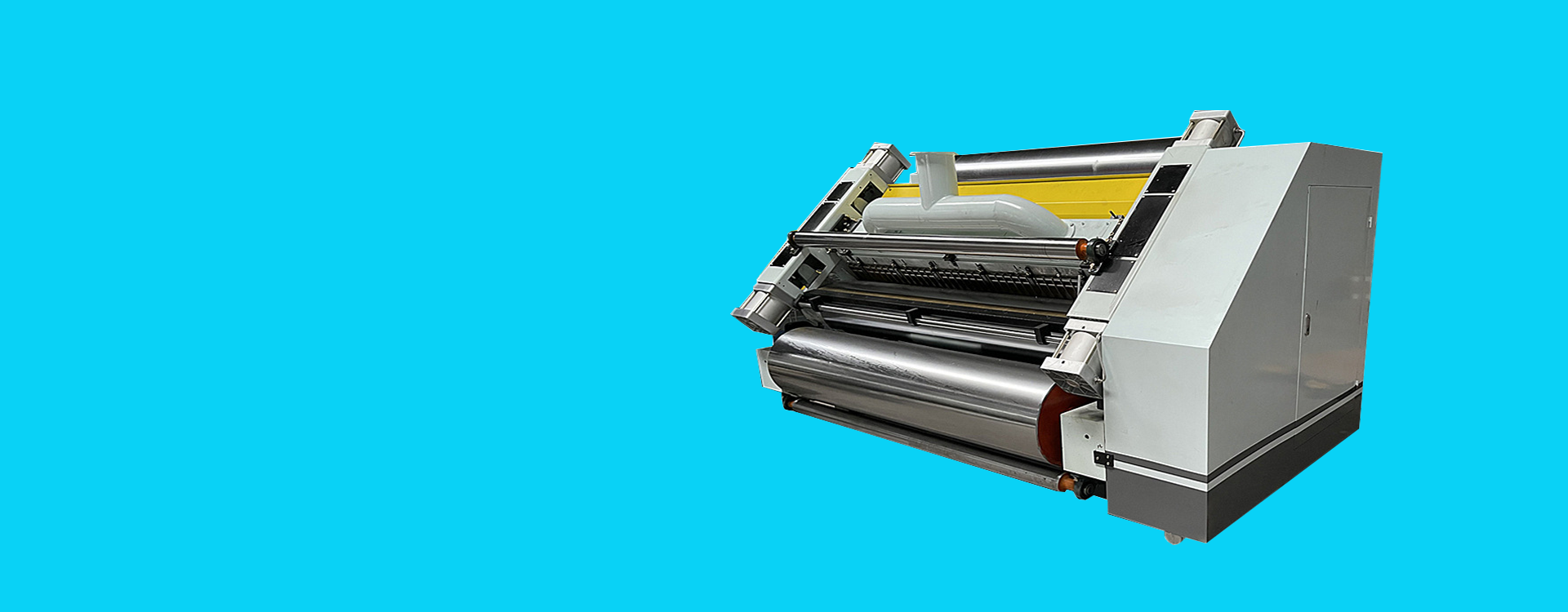

SF-280S Fingerless Type Single Facer

- Design speed: 100m/min

- Effective width: 1400mm~1800mm

- Corrugated roll: Φ280mm

- The drive reducer adopts oil immersion lubrication to reduce noise. Universal joint transmission is used to isolate the power source.

- The lifting and lowering of the upper tile wheel, pressure roller and gluing roller are all controlled pneumatically.

- The paper guiding method adopts vacuum adsorption and is equipped with an air volume regulating device to maintain the stability of the corrugated shape during high-speed transition.

- The bearings of the bearing roller and pressure roller are lubricated with high-temperature resistant grease.

- The gluing section adopts an automatic circulating supply of glue.

- The upper and lower corrugation rolls are made of high-quality 48CrMo chromium-molybdenum alloy steel, which has undergone heat treatment, with a hardness ranging from HRC580 to 600, and the surface is ground.

- The surface of the glue-coated roller is treated with mesh engraving and chrome plating.

- Manual or electric glue separator.

- The gluing part can be shut down in two modes: independent operation or non-independent operation. The main motor is controlled by frequency conversion (optional).

SF-320C Fingerless Type Single Facer

- Design speed: 150m/min

- Effective width: 1400~2200mm

- Corrugated roll: Φ320mm

- The drive reducer adopts oil immersion lubrication to reduce noise. Universal joint transmission is used to isolate the power source (optional).

- The lifting and lowering of the upper tile roller, pressure roller and gluing roller are all controlled pneumatically.

- The paper guiding method adopts vacuum adsorption and is equipped with an air volume regulating device to maintain the stability of the corrugation shape at high speed.

- The bearings of the bearing roller and pressure roller are lubricated with high-temperature resistant grease.

- The gluing section adopts an automatic circulating supply of glue.

- The upper and lower corrugating rolls are made of high-quality 48CrMo alloy steel, which has undergone heat treatment with a hardness of HV1200 or above. The surface is treated with tungsten carbide or hard chromium plating.

- The surface of the glue-coated roller is treated with mesh engraving and hard chromium plating.

- Manual or electric glue separator.

- The gluing part can be shut down in two ways: independent operation or non-independent operation.

SF-360E(320) Cassette Single Facer

- 360E design speed: 200m/min, 320E design speed: 180m/min

- Effective width: 1400mm~2200mm

- Corrugated roll: Φ360/320mm

- The negative pressure design is adopted to ensure that the core paper can be evenly pressed and adhered to the surface of the corrugating roller, and then evenly coated with glue, which makes the single-sided corrugated paper adhere better.

- Quick roll replacement, 10 minutes. When replacing corrugated rolls, use an electric vehicle to support them and send them into the machine, then fix them on the machine base to complete the corrugated roll replacement quickly and easily.

- The corrugated rolls, pressure rolls, etc. adopt the airbag control system with high stability.

- The amount of glue application is controlled by electric adjustment. The glue separation device is also electric. The glue application system can operate independently when the main unit stops to prevent the glue from drying up.

- The mobile gluing system, apart from being convenient for cleaning, is more conducive to maintenance and repair work.

- Simple operation control system, touch screen operation interface, combined with color graphic display of operation status.

- Built-in pre-adjuster with spray system, regulating the temperature and moisture of the core paper.

What is Single Facer Machine

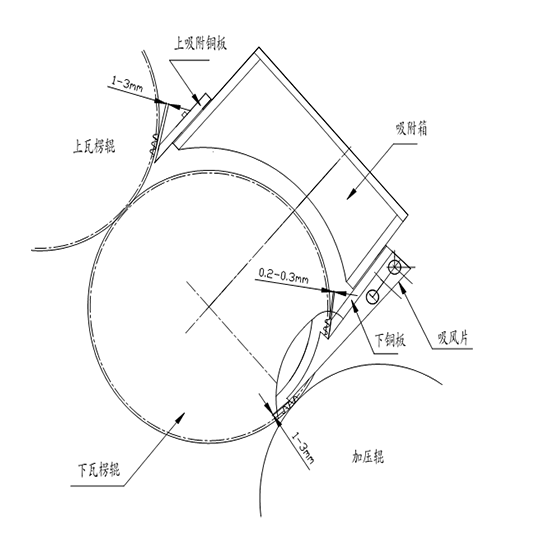

The working principle of the single-face machine mainly involves pressing the corrugated base paper into shape through the upper and lower corrugating rollers, and then applying paste to the gluing roller. This process enables the face paper and the formed corrugated paper to be bonded together at the tangential points of the pressure roller and the lower corrugating roller to form two layers of corrugated board. During this process, the single-sided machine also involves steps such as adjusting the temperature and humidity of the base paper, preheating the core paper, and forming and bonding corrugated cardboard.

Introduction to the main working parts:

The upper corrugating roller and the lower corrugating roller: Together, they form the corrugated paper. The upper corrugating roller is the driven roller, and the interlocking pressure between the two rollers is regulated by the pneumatic/hydraulic system. The lower corrugating roller is the driving roller and remains stationary.

Gluing roller: It is responsible for applying glue to the corrugation peaks of the corrugations. Its surface has concave holes similar to “honeycomb”, which is conducive to scraping the slurry.

Uniform glue roller: It controls the thickness of the glue application and can adjust the gap between it and the glue coating roller.

Pressure roller: Helps bond the face paper to the core paper. The pressure is adjustable and steam is passed through the inside.

Operating principle

The working principle of the single-sided machine can be decomposed into the following steps:

Corrugated paper forming: The corrugated base paper enters between the upper and lower corrugating rollers and is formed into a wavy shape under the pressure of the pressure rollers.

Gluing: The formed corrugated paper passes through the gluing roller, which applies glue to the corrugation peaks, preparing for the subsequent bonding of the face paper.

Bonding: The face paper and the corrugated paper that has been coated with adhesive are bonded together at the tangents of the pressure roller and the lower corrugating roller to form two layers of corrugated board.

Cardboard export: The two-layer corrugated cardboard is pulled onto the bridge by the belt to the double-sided machine section to be compounded and formed with other single corrugated cardboard and face paper.

Single facer Advantage

- Compared with traditional corrugators, single-sided machines do not have fixed resonance points, which means that during the production process, there will be no problem of unstable paper quality caused by equipment resonance, thereby improving the stability of product quality.

- The laminating system on the single-sided tape press is automatic. The laminating wheel automatically controls the gap between the corrugating roller and the laminating wheel and adjusts it automatically according to the thickness of the paper, avoiding the problem of poor adhesion of the cardboard caused by excessive or insufficient gluing amount.

- In the production of low grammage cardboard, the single-faced machine, through its design and technology, such as negative pressure suction method and belt-type pressure-free roller design, has enhanced the stability of the corrugated cardboard production line, increased the yield of cardboard products, and effectively solved the production pain points of low grammage cardboard.

- The single-sided machine is equipped with automatic control functions, such as the automatic paste quantity control system and the automatic pressure roller control system, etc. These systems can automatically adjust the paste quantity gap and the pressure roller gap according to the paper material and production speed, reducing manual intervention and improving production efficiency.

MaoWei Carton Packing Company

Hebei Maowei Packing Machinery CO.,Ltd is located in the south of the capital Beijing, the north of Jinan, water and land transportation is very convenient, is a considerable scale of the production of Carton Box Machine Manufacturer professional enterprises. Company covers an area of 3000㎡, has 100 employees. We have independent development and research capabilities, professional and rich manufacturing experience, and constantly improve the shortcomings of international and domestic packaging machinery.

- SF-280S Technical parameters

- SF-320C Technical parameters

- SF-360E(320) Technical parameters

| Width | 1400~1800mm Operation direction: left or right (according to customer’s plant) |

| Design speed | 100m/min |

| Air source | 0.4-0.9mpa |

| Heating method | Steam heating |

| Diameter of corrugating roll | ¢280mm |

| Diameter of pressure roll | ¢284mm |

| Glue roller diameter | ¢216mm |

| Diameter of preheater | ¢320mm |

| Width | 1400~2200mm Operation direction: left or right (according to customer’s plant) |

| Design speed | 150m/min |

| Temperature range | 160—180℃ |

| Diameter of corrugating roll | up¢346mm down¢320mm |

| Diameter of pressure roll | ¢370mm |

| Glue roller diameter | ¢269mm |

| Fixed paste roller¢153mmPreheater diameter | ¢402mm |

| Width | 1400~2200mm Operation direction: left or right (according to customer’s plant) |

| Design speed | 180m/min |

| Maximum temperature of steam | 180℃ |

| Maximum steam pressure | 1.2Mpa |

| Diameter of corrugating roll | ¢320mm |

| Diameter of pressure roll | ¢370mm |

| Glue roller diameter | ¢269mm |

| Fixed paste roller | ¢153mm |

| Preheater diameter | ¢400m |

Customer Review

We are manufacturer.

Sure,we have permanentfreight forwarder who can gain the best prce from mostship companyand offer professional service.

Our machines have 12 month warranty.And the engineers avaiable for overseasservice.

Yes, we accept customized services for customers and we have agents in other countries.

Parallelism adjustment of corrugated rolls in single-sided machines

The parallelism of corrugated rolls is divided into tooth parallelism and axial parallelism. Parallelism refers to the concentricity of the upper and lower corrugating roller shafts and the degree of parallelism between the corrugating teeth. If the parallelism of the corrugating rollers is not properly adjusted, it will lead to inconsistent shrinkage rates on both sides of the corrugating paper, the thickness on both sides of the corrugated paper is inconsistent or there are problems such as the corrugations being crushed, inverted corrugations, and ruffles. The parallelism of the corrugating rolls is not good. One reason is that the equipment was not adjusted properly during installation. Secondly, after a period of production, the parallelism of the corrugated rolls changes due to high temperature, high pressure and operational wear. Therefore, it is necessary to regularly inspect and calibrate the parallelism of the corrugated rolls. If the parallelism of the corrugation roller is not good, it can be calibrated slowly by adjusting the eccentric wheel on the corrugation roller. The test method can be the copying method for indentation verification, a sheet of carbon paper is sandwiched between two white sheets of paper. Then, it is placed between the two slowly rotating corrugating rolls at three positions: the operation side, the transmission side, and the center of the corrugating roll. The total thickness of the two white sheets selected should be approximately the same as that of the actual produced corrugating base paper, generally 25 to 30 microns. By the mutual meshing and rotation of the upper and lower corrugation rolls, the corrugation marks are copied from carbon paper onto white paper. The parallelism of the corrugation rolls is judged by comparing the widths and color depths of the three indentations until they are the same. When conducting the indentation test, it is necessary to appropriately reduce the pressure between the corrugating rolls, cut off the steam, and allow the temperature of the corrugating rolls to disappear before conducting the test to ensure the effect of the indentation test. Although adjusting the parallelism of corrugating rolls by this method is time-consuming, it wastes less base paper.

After receiving the deposit, 30~60days, different machines have different times.

30%TT in advance, 70% balance payment before shipping.

My company is located in the Industrial zone of Dongguang County, Cangzhou City, Hebei Province.